Bump was a 501(c)(3) nonprofit design studio that operated from 2008 to 2014.

About

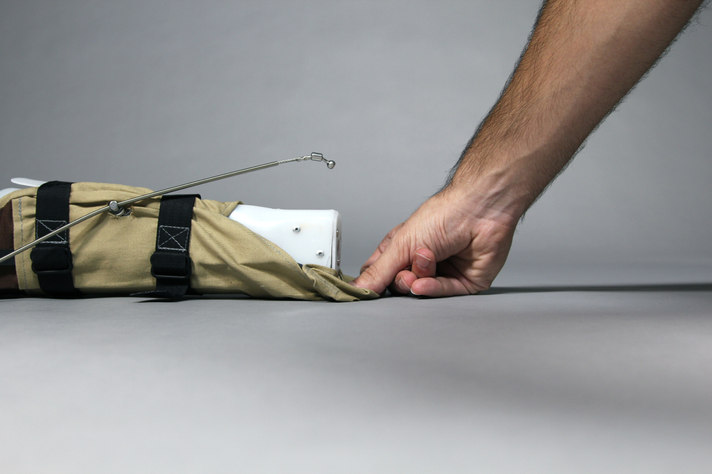

Between 2008 to 2014, we developed, tested, iterated and distributed the OpenSocket prosthetic arm — a revolutionary adjustible prosthesis designed to be fit off-the-shelf in less than 30 minutes with just a few common hand tools at 10% the cost of traditonal devices.

The OpenSocket arm was fit to over 110 patients through our network of partner organizations in Central America. Unfortunately, just as we were getting ready to scale up production to fulfill more orders, our daily operations suddenly shut down for the same reasons any startup fails — we didn't reach product-market fit fast enough.

This website documents our work and shares our learnings for any others that may be working on similar projects.

We believed that everyone deserves great design and we worked hard to make sure the OpenSocket was not only affordable but also highly functional and durable.

We applied the rigor and innovation of a startup through the lens of a nonprofit mission to create impact in prosthetic care. Our mission was to make a prosthetic arm that not only satisfied the constraints of amputees in developing countries but was also so good that amputees who already had traditional care would also choose to purchase our arm.

The hope was that through the economies of scale, quality would go up and cost would come down to truly improve global access to prosthetic care.

Team

Core Team:

Jon Naber, Adam Booher, Ehsan Noursalehi, Sudeep Gowrishankar, Ellen Walkington, Dylan Borrenpohl

Key Contributors:

Richard Kesler, Luke Jungles, Hari Vigneswaran, Natalie Dears, Nashrah Maryam, Michelle Sawa, Adam Rule, Bill Berger, Taekyeom Lee, Ali Razfar, Jon Pearce, Mona Ghadiri, Manqian Qian, Will Tham, Becca Gosling, Anne Wess, Lana Rottler, Ruth Osbrink, Aemen Hussain, and countless more...

Videos + Press

Patient Testimonial

Fitting in patient home (15min timelapse in 1 min)

1.

2.

3.

4.

Traditional prosthetic arms take between days to months to custom fabricate per patient

In developing countries, 98% of amputees do not have access to prosthetic care.

There are not enough prosthetists or prosthetic labs in the world to make enough prosthetic arms for every amputee who wants or needs one.

Traditional prosthetics fabrication requires expensive laboratories, specialized tools, and trained professionals. In developing countries, these labs and prosthetists are rare.

The problems we focused on solving

Designed to fit like a shoe

The OpenSocket takes inspiration from shoes, and uses two adjustable straps to achieve a personalized fit for every user. Built with multiple layers of plastic and fabric give it the ability to have both rigidity and extreme levels of adjustability.

Lessons Learned

We are working on distilling everything we learned from our journey to share back with the community and we are working on this with the garage door open.

Metrical font courtesy of Jess Smith